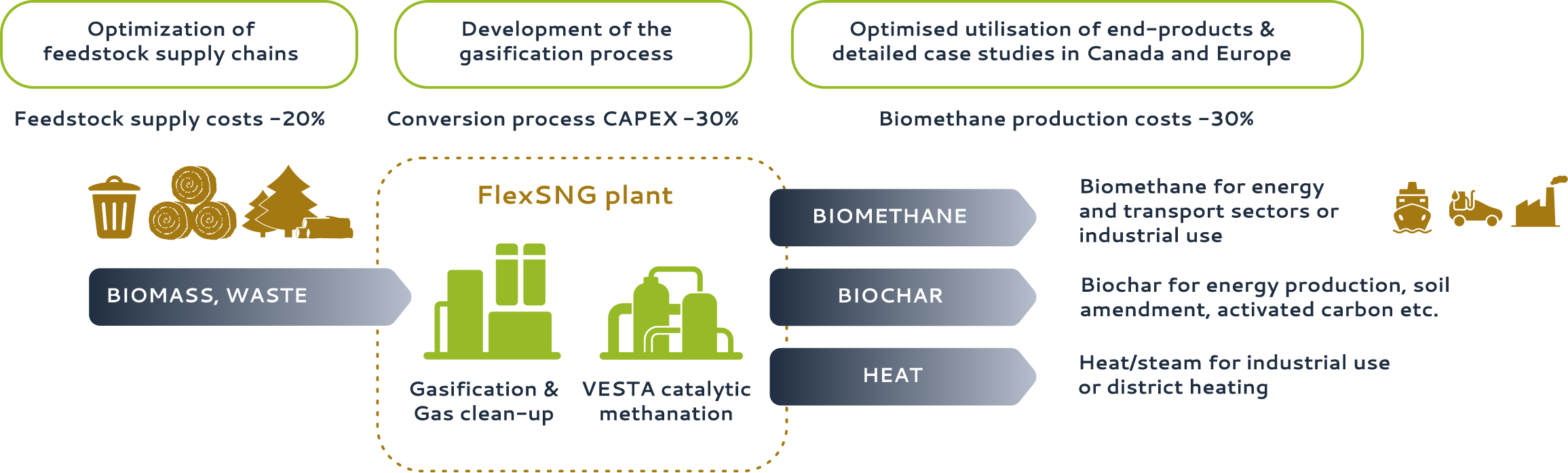

Flexible Production of Synthetic Natural Gas and Biochar via Gasification of Biomass and Waste Feedstocks

FlexSNG is a jointly funded Horizon 2020 project that aims at fostering international collaboration between the European Union and Canada in the strategic sectors of bioenergy and biofuels

The Goal

FlexSNG – New Video!

Watch this animated video to find out more about the FlexSNG H2020 Project process and objectives.

End-Products

![]()

Biomethane

Biomethane, also known as “renewable natural gas”, is a near-pure source of methane produced either by upgrading biogas or, as in FlexSNG, through the gasification of solid biomass followed by methanation. The high-purity biomethane produced in the FlexSNG process complies with the gas quality specifications of natural gas networks and can therefore be stored and distributed using the existing gas infrastructure. Biomethane can be used in various applications in energy production, transportation and industry.

Biochar

Biochar is a charcoal-like substance that is produced from biomass typically in a pyrolysis process in the absence of oxygen. In the FlexSNG process, however, biochar is formed as a by-product in gasification where feedstock conversion to gas is deliberately reduced down to 70-80% to recover the biochar from the bottom of the gasifier. Biochar is an easily storable bioenergy carrier that can be used to displace fossil feedstocks in energy production and industry or e.g. in agriculture for soil amendment.

Renewable Heat

The FlexSNG plant is integrated with local energy systems to utilise the by-product heat from the process as renewable steam to industry, or as renewable district heat to communities. Such heat integration enables high overall efficiency (>80%) that is comparable to combined heat and power production plants.

Innovations

The new gasification-based concept of FlexSNG allows reducing biomethane production costs by 30% compared to state-of-the-art biomass-to-SNG designs owing to the combination of new technology innovations in the conversion process and feedstock supply chain optimization. The target is at medium-scale conversion plants, corresponding to 50-150 MWth feedstock input, that enables the use of local biomass residues and biogenic waste fractions without heavy transport logistics.

The proposed FlexSNG activities support several of the UN Sustainable Development Goals (SDGs), in particular:

EU-Canada Cooperation

FlexSNG is built on international cooperation between European and Canadian partners allowing the project to ensure effective realisation of project activities and achievement of cost reduction targets set for both feedstock supply and conversion process. One of the key benefits of the FlexSNG process is its feedstock-flexibility, which allows for wide geographical replication of biofuels/bioenergy carriers production in Europe, Canada and beyond.

Overall Budget

€ 4.4 Million

Partners

12

Start

Duration

Latest News

FlexSNG: Media Success of an Innovative Project

FlexSNG, the international project funded by the European Union and Canada, concluded on December 31, 2024. Over its duration, the project made significant strides in

Final FlexSNG Press release

FlexSNG Project Concludes with Breakthroughs in Clean Energy Innovation The European FlexSNG project, in collaboration with the Canada’s Government, is concluding on December 31st, 2024,

FlexSNG Newsletter #6

Don’t miss our final newsletter, featuring a recap of the closing meeting, key achievements and a glimpse into the future. Read it here and stay

FlexSNG Final Event – Recording It’s Now Available

The Final FlexSNG Event, held on December 2nd, marked the culmination of this groundbreaking project, which was originally set to conclude in May but received