The concept

The H2020 project FlexSNG is an EU-Canada jointly funded action that aims at developing a flexible and cost-effective gasification-based process for the production of pipeline-quality biomethane (bio-based synthetic natural gas, bio-SNG), high-value biochar and renewable heat from a wide variety of low-quality biomass residues and biogenic waste feedstocks.

The FlexSNG gasification concept is based on the “one plant, two modes” approach where the plant can switch between:

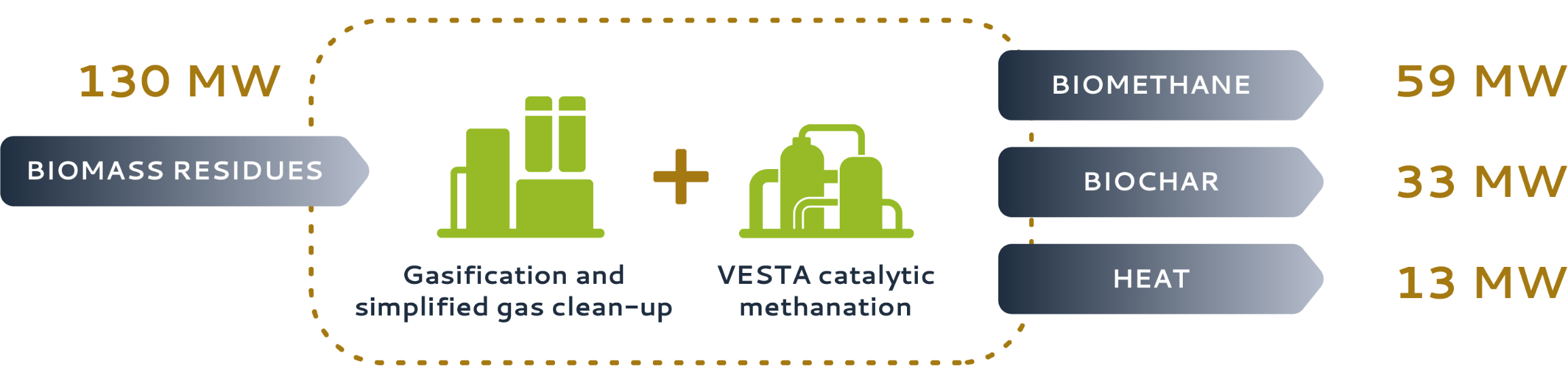

1) co-production of biomethane, biochar and heat;

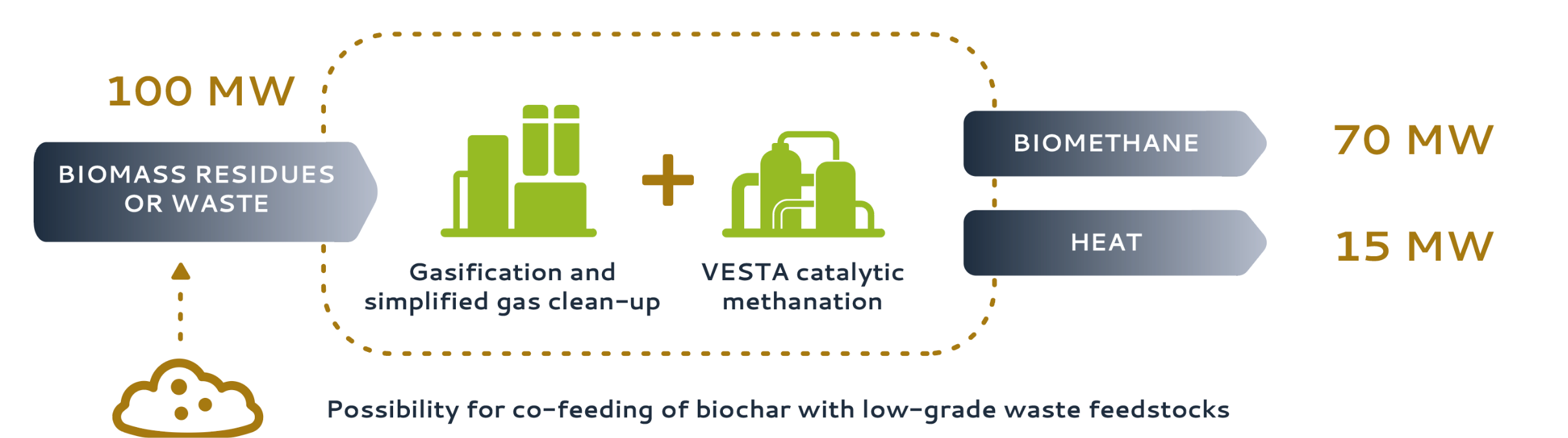

2) maximised production of biomethane and heat.

1) Co-production mode

2) Maximised production of biomethane

The key idea is that the plant can adapt to changes in market conditions or feedstock availability and price by switching operation mode. At the core of the FlexSNG plant is a flexible gasifier that either co-produces biochar and syngas or maximises syngas production:

1) In co-production mode, the aim in gasification is to restrict the feedstock carbon conversion into gas to a level of 70-80% and thus enable the production of solid biochar alongside synthesis-quality gas. This is accomplished by lowering the gasification temperature to around 700-800 °C.

2) When maximising the production of biomethane and heat, feedstock conversion into syngas is maximized in the gasifier by increasing the gasification temperature to ca. 850-900 °C and lowering the biomass throughput of the plant so that also the biomass charcoal is gasified (>99% carbon conversion achieved). One key innovative feature in this operation mode is the possibility to switch to using lower-grade waste feedstocks. This is accomplished by co-feeding biochar: mixing biochar with waste allows to “upgrade” these more challenging feedstocks into suitable feeds for gasification.

Main challenges of state-of-the-art gasification concepts VS FlexSNG solutions: